The low-voltage distribution line refers to the line that reduces the high-voltage 10KV to 380/220v level through the distribution transformer, that is, the low-voltage line sent from the substation to the equipment.

The low-voltage distribution line should be considered when designing the wiring method of the substation. For some workshops with large power consumption, the workshop is also equipped with a transformer substation. The transformer supplies power to the electrical equipment, while the For workshops with less power consumption, the power supply is directly supplied by the distribution transformer.

Low-voltage power distribution method

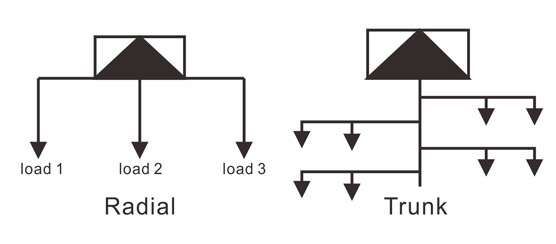

The low-voltage distribution line is designed and laid out according to the type, size, distribution and nature of the load. Generally, there are two distribution modes, radial and trunk type, as shown in the figure on the right.

Radial lines have good reliability, but high investment costs, so now low-voltage power distribution wiring is commonly used trunk type, which can obtain sufficient flexibility. When the production technology changes, the distribution line does not need to undergo major changes. The cost of electricity is relatively low, which is its two major characteristics. Of course, in terms of the reliability of power supply, it is not as good as the radial type.

Types of low-voltage distribution lines

There are two installation methods for low-voltage distribution lines, namely, cable laying method and overhead line laying method.

Because the cable line is laid underground, it has little natural impact on the outside world, such as strong wind and icing, and no wires are exposed on the ground, thus beautifying the city appearance and the environment of the building, but the investment cost of the cable line is high, and maintenance is more difficult. , the advantages of overhead lines are just the opposite. Therefore, for places without special requirements, the low-voltage wiring adopts the overhead line method.

Low-voltage overhead lines are generally made of wooden poles or cement poles to make telephone poles, and porcelain bottles are used to fix the wires on the cross-arms of the poles. The distance between the two poles is about 30~40M in the courtyard, and it can reach 40~50M in the open area. The distance between the wires is 40~60 cm. The erection of the line is as short as possible. Easy to maintain and repair.

Distribution box on construction site

Distribution boxes on construction sites can be divided into general distribution boxes, fixed distribution boxes and mobile distribution boxes.

General distribution box:

If it is an independent transformer, the transformer and the main distribution box after it are installed by the power supply bureau. The main distribution box is equipped with a total low-voltage circuit breaker, active and reactive watt-hour meters, voltmeters, ammeters, voltage transfer switches, and indicator lights. The wiring of each branch line of the construction site should be connected to the branch distribution box behind the main distribution box. If it is a pole-mounted transformer, the two distribution boxes are installed on the pole, and the lower plane of the box is more than 1.3m away from the ground. DZ series low-voltage circuit breakers are used in the distribution box. The total circuit breaker is selected according to the rated current of the transformer. Each branch line is controlled by a circuit breaker with a smaller capacity. The capacity of the circuit breaker is selected according to the maximum rated current of the circuit. If the current is small, it should be Choose a leakage switch (the maximum capacity of the leakage switch is 200A). The number of sub-circuit breakers should be one to two more than the number of designed branches as backup branches. The construction site distribution box is not equipped with current and voltmeters for monitoring.

If it is not an independent transformer, but the original transformer is used, the main distribution box and the shunt distribution box are integrated, and the active and reactive watt-hour meters are added. Starting from the main distribution box, the back line adopts TN-S three-phase five-wire system, and the metal shell of the distribution box needs to be connected to zero protection.

Fixed distribution box:

Due to the multi-purpose cable line laying on the construction site, the power supply system adopts the radial type, and each fixed distribution box is the end point of this branch, so it is generally placed near the electrical equipment of this branch.

The shell of the fixed distribution electric box is made of thin steel plate, and the top should be rainproof. The height of the box body from the ground is greater than 0.6m, and the angle steel is used as the leg support. Only 200~250A main switch, using four-pole leakage switch, the capacity is the maximum rated current of the electrical appliances in the box, considering the versatility, it can be designed according to the basic conditions of various equipment used in the construction site, such as considering that each box can be connected to a tower crane or Welder. Several shunt switches are installed behind the main switch, and four-pole leakage switches are also used, and the capacity is combined according to the specifications of common electrical appliances. For example, the main switch uses a 200A leakage switch, with four branches, two 60A and two 40A. The lower port of the shunt switch should be equipped with a porcelain plug-in fuse as an obvious disconnection point and used as the equipment wiring terminal. The upper port of the fuse is connected to the lower port of the leakage switch, and the lower port is empty for equipment wiring. When necessary, a single-phase switch should be installed in the box, ready for use with single-phase equipment.

As the end point of the branch line, in order to strengthen the reliability of the protection of the neutral line grounding. Repeat grounding is to be done at each fixed distribution box.

After the wire is introduced into the box, the working zero line is connected with the terminal board, the phase line is directly connected to the upper port of the leakage switch, and the protective neutral line is crimped on the grounding bolt on the shell of the distribution box and grounded repeatedly. After the distribution box The protection zero line is all connected to this bolt.

Mobile distribution box:

The format of the mobile distribution box is the same as that of the fixed distribution box. It is connected to the fixed distribution box with a rubber sheathed flexible cable and moved to the place as close as possible to the electrical equipment, such as from the downstairs to the upstairs construction floor. There is also a leakage switch in the box, and the capacity is smaller than that of the fixed box. A single-phase switch and socket should be installed to provide single-phase power supply for single-phase electrical appliances. The metal shell of the distribution box should be connected to zero protection.

Post time: Jun-02-2022