In sandy, rock pan and other soils with large earth resistivity, in order to meet the requirements of low grounding resistance, a grounding

grid composed of multiple grounding bodies in parallel is often used. However, sometimes a lot of steel materials are needed and the

grounding area is very large, so it is often difficult to achieve the required grounding resistance. At this time,we can try to reduce the earth

resistivity of the soil near the grounding body, and also achieve the goal of reducing the grounding resistance.

1. Use low resistivity soil (i.e. soil replacement method)

Clay, peat, black soil and sandy clay are used to replace the original soil with high electrical resistance coefficient, and coke and charcoal

can also be used if necessary. The replacement range is 1~2m around the grounding electrode and 1/3 of the grounding electrode at the

near ground side. After such treatment, the grounding resistance can be reduced to about 3/5 of the original value.

2. Artificial treatment such as adding salt

Add salt, coal cinder, carbon dust, furnace ash, coke ash, etc. to the soil around the grounding body to improve the conductivity of the soil.

The most commonly used is salt. Because salt has a good effect on improving the soil resistance coefficient, it is less subject to seasonal

changes,and the price is low. The treatment method is to dig a pit with a diameter of about 0.5~1.0m around each grounding body, and fill

salt and soil into the pit layer by layer. Generally, the thickness of salt layer is about 1cm, and the thickness of soil is about 10cm. Each layer

of salt should be wetted with water. The salt consumption of a tubular grounding body is about 30-40kg; This method can reduce the grounding

resistance to the original (1/6-1/8) for sandy soil and (2/5-1/3) for sandy clay. If you add about 10kg charcoal, the effect will be better. As charcoal

is a solid conductor, it will not be dissolved, penetrated and corroded, so its effective time is long. For flat steel, round steel and other parallel

grounding bodies, better results can be obtained by using the above methods. However, this method also has disadvantages, such as little effect

on rocks and soil with more rocks; The stability of grounding body is reduced; It will accelerate the corrosion of grounding body; The ground

resistance will slowly increase due to the gradual melting and loss of salt. Therefore, it needs to be treated once about 2 years after manual treatment.

3. External grounding

Especially in hilly areas, when the grounding resistance value is required to be small and difficult to reach in situ, if there is water source or

soil with low resistance coefficient nearby, the place can be used to make grounding electrodes or lay underwater grounding grid. Then, use

the grounding wire (such as flat steel strip) to connect it as the external grounding. However, it should be noted that the external grounding

device should avoid the pedestrian channel to prevent electric shock caused by step voltage; When crossing the highway, the buried depth of

the external lead shall be no less than 0.8m.

4. Conductive concrete

Carbon fiber is mixed into cement to be used as grounding electrode. For example, about 100kg of carbon fiber is added into 1m3 of cement

to make a hemispherical (1m in diameter) grounding electrode. Through measurement, its power frequency grounding resistance (compared

with ordinary concrete) can generally be reduced by about 30%. This method is often used for lightning protection and grounding devices. In

order to further reduce the impulse grounding resistance, the needle shaped grounding electrode can also be embedded in the conductive

concrete at the same time, so that the discharge corona can continuously ground wave and carbon fiber from the needle tip, which has an

obvious effect on reducing the impulse grounding resistance.

5. Chemical treatment with drag reducing agent

The resistance reducing agent using carbon powder and quicklime as the main raw materials can be used in the soil for a long time and will

not be lost due to the groundwater because it does not contain dielectric, so it can obtain a long-term pollution-free and stable low grounding

resistance (about 1/2 lower than that before using the resistance reducing agent to treat the soil). For hard rock plate zone, the method of

burying grounding wire and resistance reducing agent is quite effective, and its grounding resistance can be reduced by about 40% compared

with that of burying only grounding wire. In addition, this method can achieve good results as long as powdery resistance reducing agent or

long-acting resistance reducing agent is sprinkled in the trench excavated and laid with grounding wire, and then the old soil is backfilled.

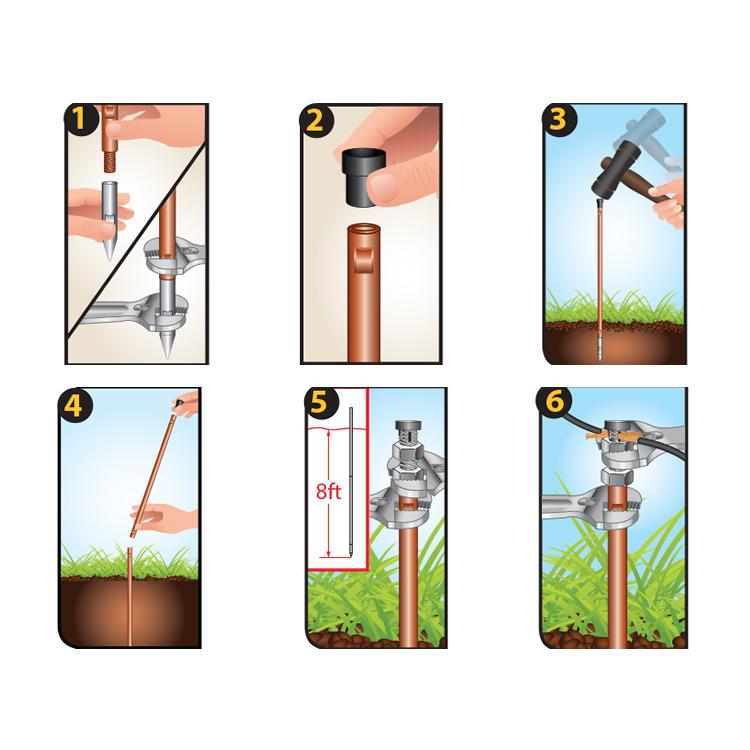

6. Borehole deep burial method

This method has been reported abroad for a long time, and has achieved good results in practical use. In recent years, China has also

begun to use this new method of resistance reduction. The length of the vertical grounding body used in this method is generally 5~10m

depending on the geological conditions. If it is longer, the effect will not be obvious and the construction will be difficult. The grounding

body usually adopts Φ 20~75mm round steel. The influence of round steel with different diameters on the grounding resistance is very

small. This method is applicable to crowded buildings or narrow areas where grounding grids are laid. In these situations, it is difficult to

find the proper position of buried grounding electrode with traditional methods, and the safe distance cannot be guaranteed. Although the

safety can be ensured by covering the grounding body with asphalt insulating layer, the construction workload and installation cost are

increased. The deep burial method is the most effective method for sandy soil, because most of its sandy layers are in the surface layer

within 3m, while the soil resistivity in the deep layer is low. In addition, the method is also applicable to rocky rock plate areas.

During construction Φ Small manual auger or drilling machine with a diameter of 50mm and above. Buried in the drilled hole Φ 20~75mm

round steel grounding body, and then filled with carbon mortar (mixed with carbon fiber water slurry) or slurry. Finally, several grounding

bodies with the same treatment are connected in parallel to form a complete grounding body. The grounding body constructed by this method

is less affected by seasons and can obtain stable grounding resistance. At the same time, due to the deep burial, the step voltage can also be

significantly reduced, which is very beneficial to the protection of personal safety. This method is convenient in construction, low in cost and

remarkable in effect, which will be popularized and applied.

Post time: Nov-05-2022