Cable connectors are an essential part of any electrical wiring system. These connectors provide a safe and efficient method of joining two or more wires together. However, not all connectors are created equal. For aluminum wire there are specific cable connectors designed for optimum performance. In this article, we explore cable connectors for aluminum wire, including recommended wires and considerations for their use.

Product use environment

Before we dive into the details, it's important to understand the context in which the product will be used. Aluminum wire is commonly used in electrical wiring systems due to its light weight and good electrical conductivity. However, these wires have some unique issues, such as being prone to corrosion, which can cause the wires to break or malfunction. For cable connectors, getting the right connector designed for aluminum wire is critical and it is recommended that you research jumper splice requirements before attempting installation.

Precautions for use

Be sure to follow certain precautions when connecting aluminum wires. For example, you should avoid cable connectors designed for copper wire. Copper wire connectors often have a different composition than aluminum connectors and may react with the aluminum wire in the long run, causing corrosion and disconnection. This could result in a potential fire hazard and safety risk. It is important to use connectors designed for aluminum wire.

Cable Connector Type

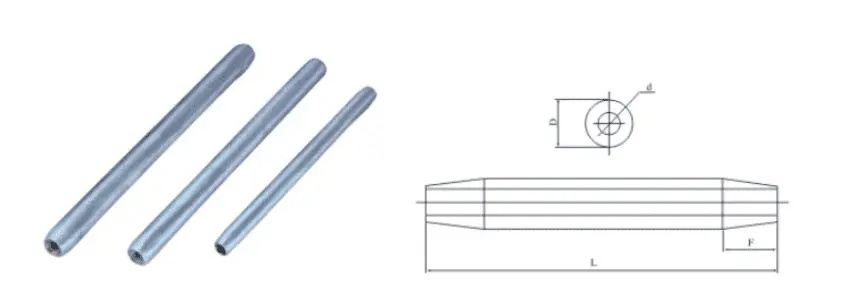

There are many types of cable connectors for aluminum wire, but some popular connectors include partial tension (40% rated tension) wire jumper splices and compressed (compact) conductor sizes in the same decade conductor range. These types of connectors can be used with wires such as 5005, ACSR, ACAR, and 6201. They are designed to provide a secure, long-lasting connection that can withstand the unique properties of aluminum wire. However, it is important to remember that different types of aluminum wire may require different types of connectors.

connector material

When selecting a cable connector for aluminum wire, it is important to ensure that it is made of high-quality materials. The recommended material for aluminum wire cable connectors is 99.5% or greater aluminum alloy (AL). This is because connectors made of pure aluminum are very flexible, while alloys provide the required strength and durability.

final thoughts

Aluminum wire cable connectors play a vital role in electrical wiring systems. Despite their unique properties, aluminum wires help ensure your connections remain safe and efficient. Remember to always research jumper splice requirements and follow the manufacturer's recommendations for connecting different wire variants. By following the recommended patch cord splice requirements, using the correct connector type, and observing necessary precautions, you can ensure a safe and reliable connection to your home or business.

Post time: May-05-2023