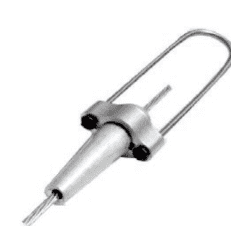

Factory Cheap Hot Edpm Cold Shrink Tube - 1 KV Heat Shrinkable Straight Joint – Yongjiu

Factory Cheap Hot Edpm Cold Shrink Tube - 1 KV Heat Shrinkable Straight Joint – Yongjiu Detail:

1- Core

| Type | Fit for cable(mm²) | Length(mm) |

| JSY-1/1.0 | 10-16 |

Can be produced according to customer’s requirement |

| JSY-1/1.1 | 25-50 | |

| JSY-1/1.2 | 70-120 | |

| JSY-1/1.3 | 150-240 | |

| JSY-1/1.4 | 400-500 |

2- Cores

| Type | Fit for cable(mm²) | Length(mm) |

| JSY-1/2.0 | 10-16 |

Can be produced according to customer’s requirement |

| JSY-1/2.1 | 25-50 | |

| JSY-1/2.2 | 70-120 | |

| JSY-1/2.3 | 150-240 |

3- Cores

| Type | Fit for cable(mm²) | Length(mm) |

| JSY-1/3.0 | 10-16 |

Can be produced according to customer’s requirement |

| JSY-1/3.1 | 25-50 | |

| JSY-1/3.2 | 70-120 | |

| JSY-1/3.3 | 150-240 |

4- Cores

|

Type |

Fit for cable(mm²) |

Length(mm) |

|

JSY-1/4.0 |

10-16 |

Can be produced according to customer’s requirement |

|

JSY-1/4.1 |

25-50 |

|

|

JSY-1/4.2 |

70-120 |

|

|

JSY-1/4.3 |

150-240 |

5- Cores

|

Type |

Fit for cable(mm²) |

Length(mm) |

|

JSY-1/5.0 |

10-16 |

Can be produced according to customer’s requirement |

|

JSY-1/5.1 |

25-50 |

|

|

JSY-1/5.2 |

70-120 |

|

|

JSY-1/5.3 |

150-240 |

Feature

1.Preferable electrical appliance function

2.Reliable insulation

3.Superior hermetic sealing

4.Excellent heat /cold proof, waterproof, Anti-aging ,

5.Widely used at the field of electric power, electronic, petroleum, chemical engineering, construction and communication

The production of heat shrinkable tubing must first select the appropriate masterbatch, and then select the auxiliary materials to produce specific

The thermal housing casing.

1. The production process of heat shrinkable tube is firstly the production of polyene leech masterbatch: combining various polyene leech base materials with various functional auxiliary materials

The materials are weighed according to the formula ratio and then mixed: the mixed materials are put into a twin-screw extruder and pelletized to produce a polyene leech functional masterbatch.

2. Product molding process: according to the shape of the product, two methods of single screw extrusion and injection molding can be used.

For processing and production:

1. Single-screw extrusion type: mainly used for extrusion molding of heat sink pipes, such as single-wall heat-shrinkable tubes, double-wall heat-shrinkable tubes with glue, and medium thickness

Wall heat sink pipes, high pressure busbar heat sink pipes, high temperature heat shrinkable pipes and other products are all processed and formed by single screw extrusion.

The heat shrinkable tube production line should have the following equipment: extruder (heat sink tube forming), production mold, cooling water tank, tension device, and

Disk device, etc.

2. Injection molding: mainly used for the production of heat-shrinkable special-shaped parts, such as heat sink caps, heat-shrinkable umbrella skirts, heat-shrinkable finger cots and other products

They all use injection molding, and production equipment should include injection molding machines and injection molds.

3. The next important step is radiation cross-linking. The products formed by extrusion or injection molding are still linear molecular structures.

Structure, the product does not yet have the “memory function”, and the performance of temperature resistance, aging resistance, and wear resistance is not enough.

Change the molecular structure of the product. The method we usually use is radiation crosslinking modification: electron accelerator radiation crosslinking, cobalt source radiation

Cross-linking, peroxide chemical cross-linking, at this time the molecule changes from a linear molecular structure to a network structure. Extruded products are passing

After cross-linking, it has a “memory effect”, which greatly enhances the temperature resistance, mechanical properties, and chemical properties of the heat shrinkable tube. The specific table

Now the heat sink tube has changed from the state of tolerance to incompatible, aging resistance, abrasion resistance, and chemical corrosion resistance.

4. Expansion molding: The product modified by radiation crosslinking already has a “shape memory effect”, and it has a high

Non-melting performance under temperature. After heating at high temperature, vacuum blowing and cooling, it becomes the finished heat shrinkable tube, and then according to the tube

The actual situation of the finished product packaging and closing can also be cut and printed according to customer needs. Neutral normal packaging is also available.

Q:CAN YOU HELP US IMPROT AND EXPORT?

A:We will have a professional team to serve you.

Q:WHAT’S THE CERTIFICATES DO YOU HAVE?

A:We have certificates of ISO,CE, BV,SGS.

Q:WHAT’S YOUR WARRANTY PERIOD?

A:1 year in general.

Q:CAN YOU DO OEM SERVICE?

A:YES,we can.

Q:WHAT YOU LEAD TIME?

A:Our standard models are in stock ,as for big orders ,it take about 15 days.

Q:CAN YOU PROVIDE FREE SAMPLES?

A:Yes,please contact us to know the sample policy.

Product detail pictures:

Related Product Guide:

We're committed to providing easy,time-saving and money-saving one-stop purchasing service of consumer for Factory Cheap Hot Edpm Cold Shrink Tube - 1 KV Heat Shrinkable Straight Joint – Yongjiu , The product will supply to all over the world, such as: New Orleans, South Korea, Mexico, Our company regards "reasonable prices, high quality,efficient production time and good after-sales service" as our tenet. We hope to cooperate with more customers for mutual development and benefits in future. Welcome to contact us.

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!